Inventory optimization is no longer a ‘nice-to-have’ – it’s a critical business imperative. In today’s dynamic marketplace, inefficient inventory management can lead to significant financial losses, lost sales, and operational inefficiencies. Inventory optimization is the process of strategically managing stock levels to meet demand while minimizing holding costs and maximizing profitability. It’s a complex undertaking, requiring a holistic approach that considers various factors, from forecasting to warehousing and distribution. This article will delve into the core strategies and techniques used to achieve truly effective inventory management, providing actionable insights for businesses of all sizes. Understanding the principles of inventory optimization is essential for long-term success.

The Importance of Effective Inventory Management

The sheer volume of goods businesses handle today – from raw materials to finished products – presents a significant challenge. Traditional methods often struggle to keep pace with fluctuating demand, leading to overstocking, stockouts, and ultimately, lost revenue. Poor inventory management can result in increased storage costs, obsolescence, and the risk of damage or theft. Furthermore, inaccurate forecasting and insufficient visibility into inventory levels can lead to missed sales opportunities and dissatisfied customers. Investing in robust inventory management systems and processes is therefore a strategic investment in the future of the business. Consider the impact of a sudden surge in demand – a well-executed inventory strategy can prevent a crisis, while a reactive approach can exacerbate the problem. The consequences of inaction can be substantial, impacting profitability and competitive advantage.

Forecasting Techniques: Predicting Demand with Accuracy

Accurate forecasting is the cornerstone of effective inventory management. It’s not enough to simply rely on historical sales data; businesses need to employ sophisticated forecasting techniques to anticipate future demand. Several methods are commonly used, each with its own strengths and weaknesses. Time series analysis, which examines past sales trends, is a foundational technique. However, it’s often limited by the assumption that past patterns will continue into the future. Regression analysis can incorporate external factors like seasonality, promotions, and economic indicators to refine forecasts. Statistical models, such as moving averages and exponential smoothing, provide a more dynamic approach, adjusting forecasts based on current trends. Qualitative forecasting, which relies on expert opinions and market research, is particularly useful for industries with complex or uncertain demand patterns. Combining these methods often yields the most reliable results. Regularly reviewing and adjusting forecasts based on actual performance is crucial for continuous improvement.

Storage and Warehouse Optimization

The physical space used to store inventory significantly impacts operational costs and efficiency. Warehouse layout is a critical consideration, optimizing flow and minimizing travel distances. ABC analysis categorizes inventory based on its value and demand, allowing businesses to prioritize storage and handling efforts. Vertical storage – utilizing higher shelves and racking systems – can maximize space utilization. Just-in-Time (JIT) inventory aims to minimize inventory levels by receiving goods only when they are needed for production or sale. While JIT offers significant benefits, it requires a high degree of trust in suppliers and robust logistics. Implementing a Warehouse Management System (WMS) provides real-time visibility into inventory levels, track shipments, and automate many warehouse processes. Investing in appropriate technology is essential for streamlining operations and reducing errors.

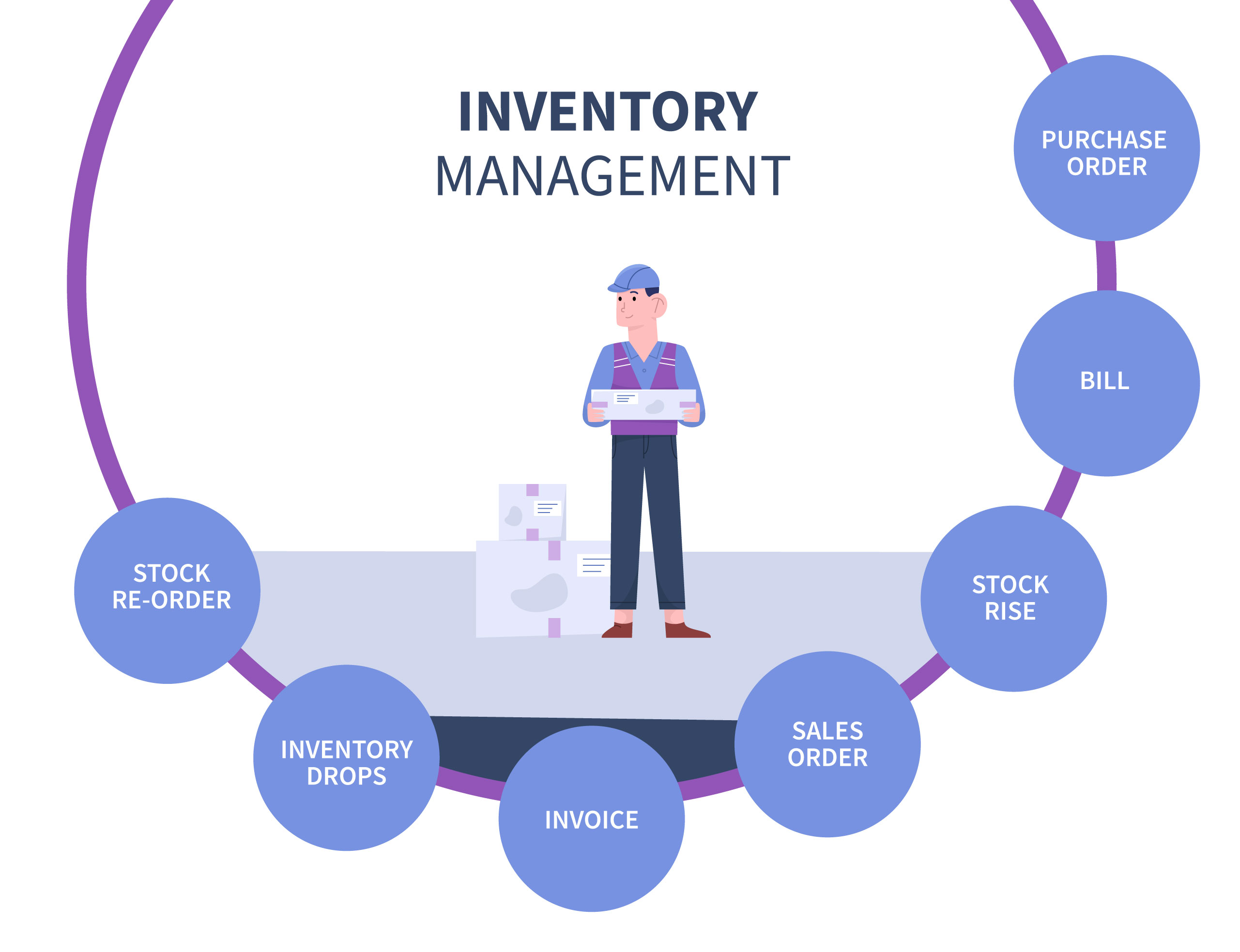

Order Management and Fulfillment

Efficient order management is vital for customer satisfaction and operational efficiency. Order processing involves verifying orders, generating picking lists, and preparing shipments. Shipping and logistics are critical for timely delivery. Order fulfillment encompasses the activities involved in packing and shipping orders. Automated order processing systems can significantly reduce manual effort and improve accuracy. Selecting the right shipping carriers based on cost, speed, and reliability is essential. Implementing a robust returns management process is crucial for customer retention and minimizing losses. Real-time tracking allows customers to monitor the status of their orders, enhancing transparency and building trust. Poor order fulfillment can quickly damage customer relationships.

Inventory Control Techniques: Minimizing Waste and Maximizing Value

Beyond forecasting and storage, effective inventory control relies on a range of techniques. Cycle counting involves regularly counting a small portion of inventory to verify accuracy. Physical inventory counts provide a comprehensive assessment of stock levels. Safety stock is a buffer of inventory held to protect against unexpected demand surges or supply chain disruptions. Economic order quantity (EOQ) provides a mathematical formula for determining the optimal order quantity to minimize total inventory costs. Vendor-managed inventory (VMI) allows suppliers to manage inventory levels at the customer’s location. Implementing a barcode scanning system streamlines inventory tracking and reduces errors. Regular audits identify discrepancies and potential problems. Implementing a robust system for tracking obsolescence is crucial for minimizing losses due to expired or damaged goods.

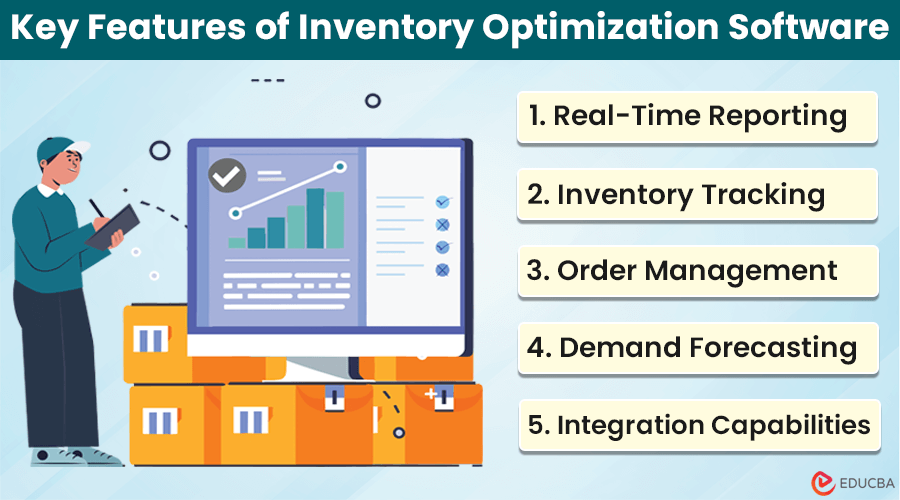

The Role of Technology in Inventory Optimization

Technology plays a pivotal role in modern inventory management. Enterprise Resource Planning (ERP) systems integrate various business functions, including inventory management, accounting, and sales. Inventory management software provides specialized tools for tracking, forecasting, and optimizing inventory levels. Radio frequency identification (RFID) technology offers enhanced tracking capabilities, improving accuracy and efficiency. Artificial intelligence (AI) and machine learning (ML) are increasingly being used to analyze vast amounts of data and predict demand with greater accuracy. Cloud-based solutions offer scalability and accessibility, allowing businesses to manage inventory from anywhere. Choosing the right technology is a critical decision, considering factors like cost, integration capabilities, and scalability.

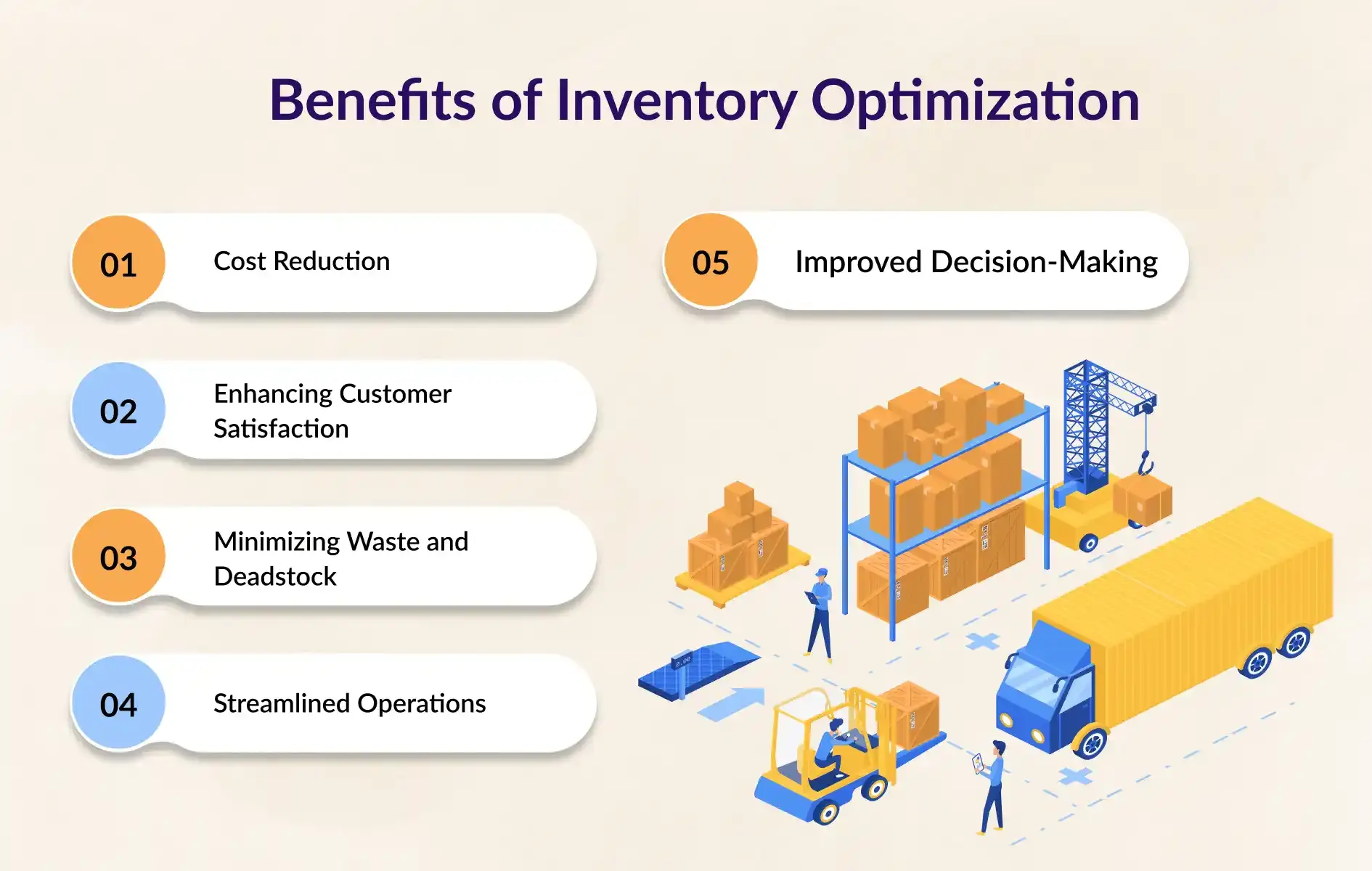

Benefits of Successful Inventory Optimization

The benefits of implementing effective inventory management strategies are numerous and far-reaching. Reduced inventory costs – through minimizing holding costs, obsolescence, and waste. Improved customer service – through ensuring product availability and timely delivery. Increased operational efficiency – through streamlining processes and reducing manual effort. Enhanced profitability – through maximizing revenue and minimizing losses. Reduced risk – through minimizing the risk of stockouts and obsolescence. Improved decision-making – through providing data-driven insights into inventory levels. Ultimately, inventory optimization is a strategic investment that delivers tangible returns for businesses of all sizes.

Conclusion

Inventory optimization is not a one-time project; it’s an ongoing process of continuous improvement. It requires a commitment from leadership, a data-driven approach, and a willingness to embrace new technologies. By understanding the principles of inventory optimization, implementing effective strategies, and leveraging the right tools, businesses can unlock significant value and achieve sustainable success in today’s competitive marketplace. The key is to move beyond simply tracking inventory and focus on proactively managing it to meet customer needs and maximize profitability. Remember, inventory optimization is a journey, not a destination. Continuous monitoring, analysis, and adaptation are essential for long-term success.