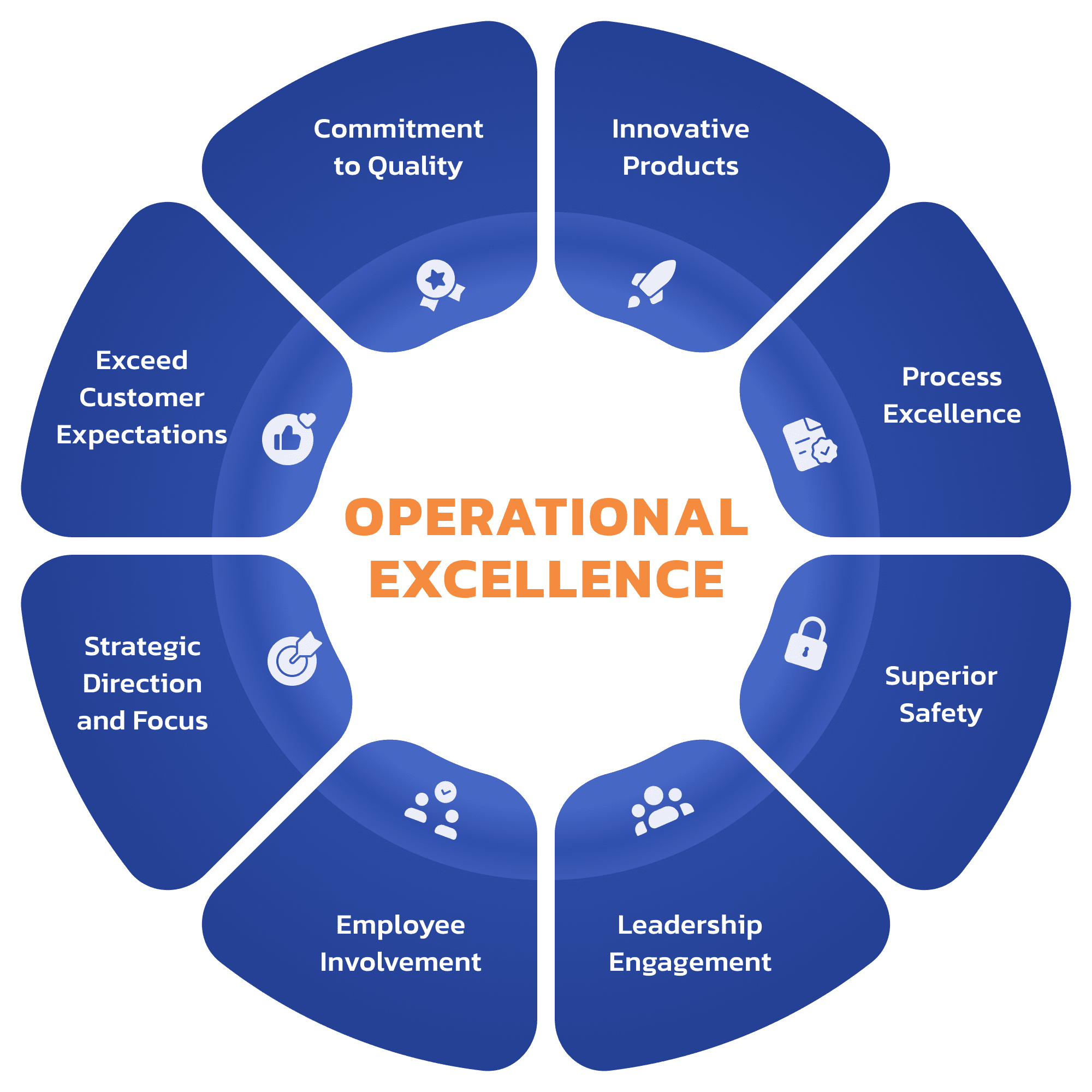

Operational excellence is no longer a buzzword; it’s a fundamental requirement for sustained success in today’s competitive landscape. Businesses that prioritize operational excellence are not simply improving efficiency; they’re fundamentally reshaping their approach to delivering value to customers, fostering innovation, and achieving a sustainable competitive advantage. This article will delve into the core principles of operational excellence, exploring its key components and providing practical strategies for implementation. Operational excellence is about consistently achieving superior performance across all aspects of your business – from production and supply chain to customer service and internal processes. It’s a journey, not a destination, requiring continuous improvement and a commitment to data-driven decision-making. It’s about understanding why things happen and then proactively designing systems and processes to minimize disruptions and maximize positive outcomes. Ultimately, operational excellence translates into increased profitability, reduced costs, and a stronger brand reputation.

Defining Operational Excellence

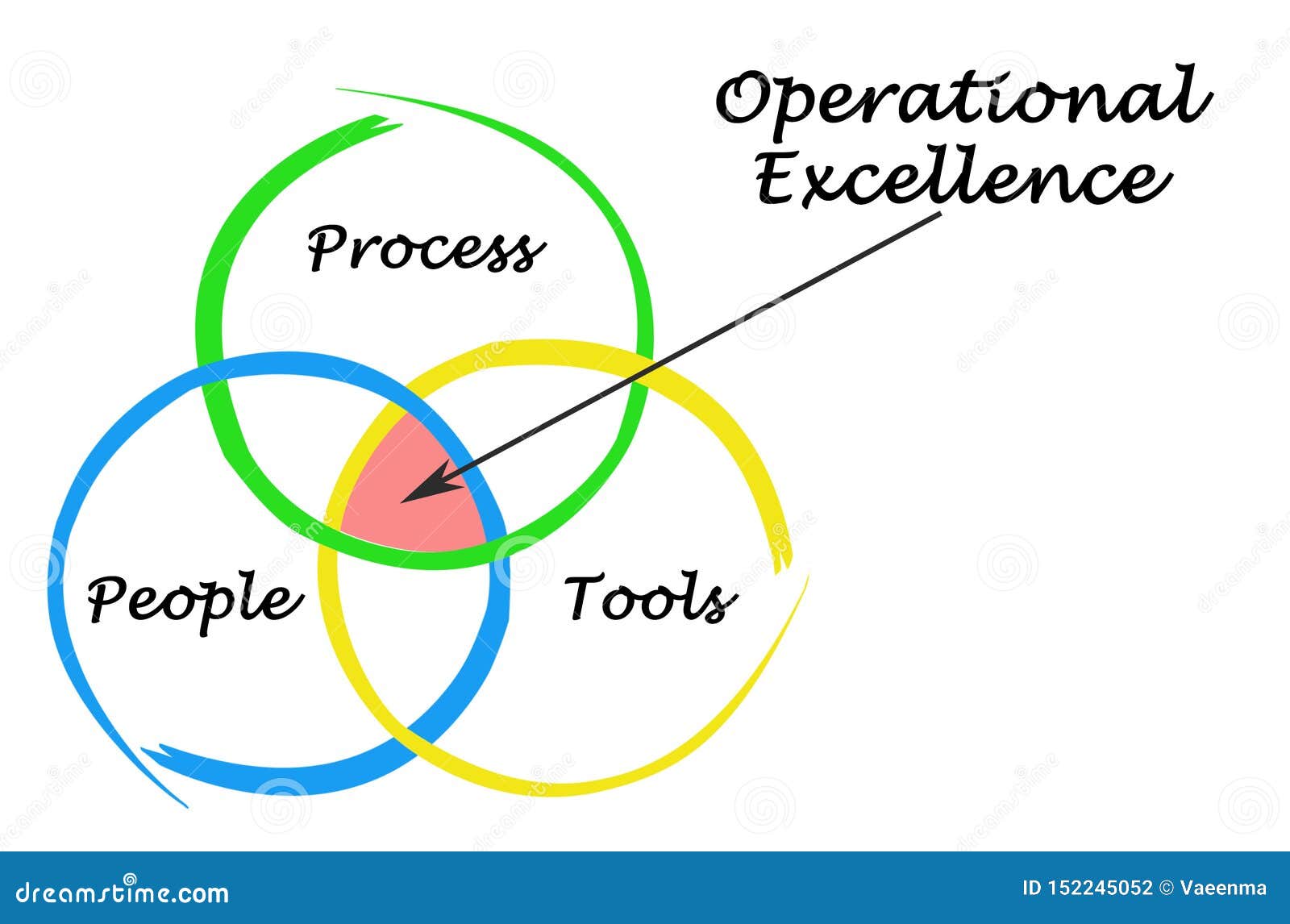

At its heart, operational excellence is a holistic approach to managing and optimizing business processes. It’s about identifying and eliminating waste, streamlining workflows, and empowering employees to perform at their best. It’s not just about reducing costs; it’s about delivering superior value to customers through consistently high-quality products or services. A truly operational excellence-driven organization anticipates challenges, proactively addresses them, and continuously seeks ways to improve. It’s a culture shift, demanding a fundamental change in mindset and behavior. It’s about recognizing that every process, no matter how small, has the potential to impact the bottom line. Furthermore, operational excellence necessitates a deep understanding of the entire value chain – from raw materials to final delivery – and the interconnectedness of all activities. It’s about moving beyond simply reacting to problems to anticipating and preventing them.

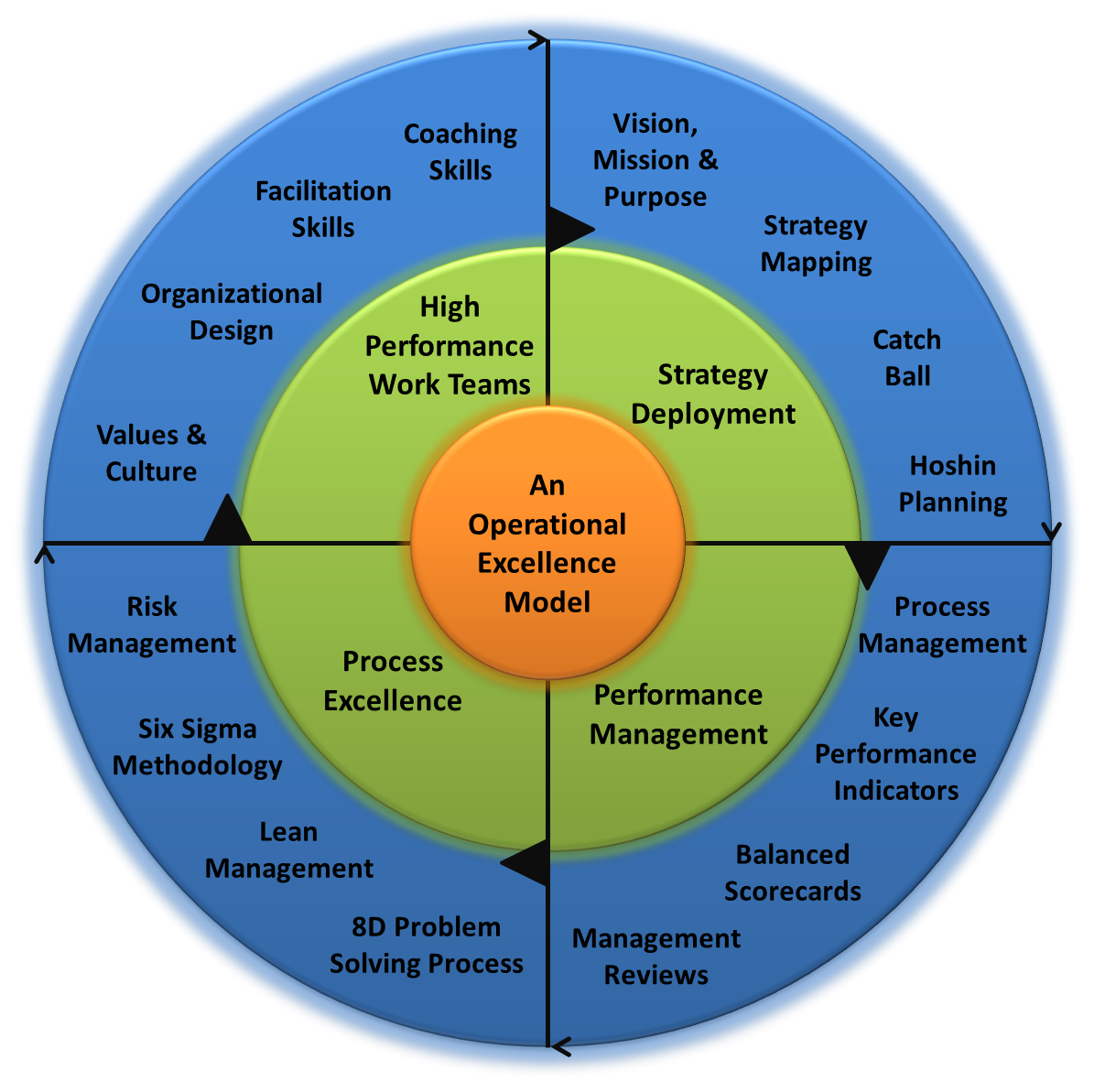

Key Pillars of Operational Excellence

Several key pillars underpin successful operational excellence initiatives. Firstly, process optimization is paramount. This involves systematically analyzing and redesigning existing processes to eliminate bottlenecks, reduce cycle times, and improve efficiency. Techniques like Lean Manufacturing and Six Sigma are frequently employed to identify and eliminate waste. Secondly, technology integration plays a crucial role. Implementing appropriate technology solutions – such as Enterprise Resource Planning (ERP) systems, Customer Relationship Management (CRM) software, and automation tools – can significantly enhance visibility, streamline workflows, and improve data accuracy. Thirdly, employee empowerment is essential. Creating a culture where employees are encouraged to identify and suggest improvements, and where they have the authority to make decisions, fosters a sense of ownership and accountability. Finally, data-driven decision-making is critical. Collecting and analyzing data – both quantitative and qualitative – allows organizations to track performance, identify trends, and make informed decisions about resource allocation and process improvement. Without this data foundation, any efforts to improve operational excellence are likely to be ineffective.

Streamlining Production Processes

Production processes are often a major source of waste and inefficiency in many businesses. A robust operational excellence strategy must address this head-on. One of the most effective approaches is to implement Lean Manufacturing principles, focusing on eliminating waste (Muda) – such as overproduction, waiting, transportation, inventory, motion, and defects. This involves a continuous cycle of identifying, analyzing, and eliminating these wastes. Another key element is Just-in-Time (JIT) inventory management, which aims to minimize inventory levels while ensuring that materials arrive when needed. Furthermore, automation can significantly improve efficiency and reduce labor costs. Robotics and automated systems can handle repetitive tasks, freeing up human workers to focus on more complex and value-added activities. However, automation should be implemented strategically, considering the potential impact on employee skills and job roles. It’s important to remember that automation is a tool, not a replacement for human expertise. Proper training and change management are crucial for successful implementation.

Supply Chain Optimization

The supply chain is a complex network of suppliers, manufacturers, distributors, and retailers. Operational excellence extends beyond the production floor to encompass the entire supply chain. Supply chain visibility is increasingly important, allowing businesses to track materials and products throughout the entire process, from raw materials to the end customer. This visibility enables proactive identification and resolution of potential disruptions, such as delays or shortages. Supplier relationship management is also critical. Building strong, collaborative relationships with suppliers can lead to improved quality, reduced costs, and greater responsiveness. Demand forecasting is essential for optimizing inventory levels and minimizing the risk of stockouts or excess inventory. Implementing collaborative planning, forecasting, and replenishment (CPFR) can significantly improve supply chain performance. This involves sharing information and coordinating activities with key suppliers and customers. Ultimately, a well-managed supply chain is the backbone of operational excellence.

Enhancing Customer Service

Customer service is often a key differentiator in today’s competitive market. Operational excellence can dramatically improve customer service by streamlining processes, reducing response times, and empowering employees to resolve customer issues quickly and effectively. Customer relationship management (CRM) systems are essential for understanding customer needs and preferences. Self-service portals allow customers to resolve common issues independently, reducing the burden on customer service representatives. Omnichannel support – providing seamless support across multiple channels (e.g., phone, email, chat, social media) – enhances customer satisfaction. Service recovery – promptly addressing and resolving customer complaints – is crucial for maintaining customer loyalty. Employee training focused on empathy, problem-solving, and communication is vital. Finally, feedback mechanisms – such as surveys and customer reviews – provide valuable insights into areas for improvement. A commitment to consistently exceeding customer expectations is a hallmark of operational excellence.

Implementing Operational Excellence – A Framework

Implementing operational excellence requires a strategic and phased approach. First, assess your current state – identify areas for improvement and prioritize initiatives based on their potential impact. Second, develop a clear vision and goals – define what operational excellence looks like for your organization. Third, establish a framework – this could include a methodology like Six Sigma or Lean, or a more holistic approach. Fourth, build a team – assemble a cross-functional team with the right skills and expertise. Fifth, implement changes incrementally – start with pilot projects to test new processes and gather feedback. Sixth, monitor and measure – track key performance indicators (KPIs) to assess the effectiveness of your initiatives. Seventh, continuously improve – operational excellence is not a one-time project; it’s an ongoing journey. Finally, communicate progress – keep stakeholders informed of your achievements and challenges.

The Role of Technology in Operational Excellence

Technology is no longer a supporting element of operational excellence; it’s an integral part of the solution. Business Process Management (BPM) software provides a centralized platform for managing and optimizing business processes. Robotic Process Automation (RPA) automates repetitive tasks, freeing up human workers for more strategic work. Cloud computing provides scalable and cost-effective infrastructure for supporting business operations. Data analytics provides insights into performance and identifies opportunities for improvement. Internet of Things (IoT) enables the collection of real-time data from equipment and processes, providing valuable insights for predictive maintenance and process optimization. Choosing the right technologies is crucial – selecting solutions that align with your specific needs and goals. Proper implementation and integration are key to realizing the full potential of technology.

Measuring Operational Excellence – Key Performance Indicators (KPIs)

Several KPIs are essential for measuring the effectiveness of operational excellence initiatives. Cycle time – the time it takes to complete a process – is a critical metric. Defect rate – the number of defects per unit of output – indicates the quality of your processes. Overall equipment effectiveness (OEE) – a measure of how well your equipment is performing – provides a comprehensive view of efficiency. Customer satisfaction – measured through surveys and feedback – reflects the impact of your operations on customer experience. Inventory turnover – measures how quickly inventory is sold and replenished – indicates the efficiency of your supply chain. Cost per unit – provides insights into the cost of producing each unit of output – helps identify areas for cost reduction. Regularly tracking and analyzing these KPIs allows you to identify trends, pinpoint areas for improvement, and demonstrate the value of operational excellence.

Conclusion

Operational excellence is a strategic imperative for organizations seeking to thrive in today’s dynamic business environment. It’s not simply about reducing costs; it’s about delivering superior value to customers, fostering innovation, and achieving a sustainable competitive advantage. By embracing the principles of process optimization, technology integration, employee empowerment, and data-driven decision-making, businesses can transform their operations and achieve remarkable results. The journey towards operational excellence is a continuous process of improvement, requiring a commitment to data, collaboration, and a relentless focus on delivering exceptional results. Ultimately, operational excellence is about creating a culture of continuous improvement, where every employee understands their role in achieving organizational goals. Investing in operational excellence is an investment in the future of your business.