Optimizing your business processes is no longer a luxury – it’s a necessity for survival and growth in today’s competitive landscape. Businesses of all sizes are constantly seeking ways to streamline operations, reduce costs, improve efficiency, and ultimately, enhance profitability. Business process optimization strategies are the key to unlocking these benefits. This article will delve into the core principles and practical techniques for identifying, analyzing, and implementing effective changes to your workflows, leading to significant improvements across the board. We’ll explore various methodologies and tools, providing actionable insights you can immediately apply to your organization. Let’s begin.

Understanding the Importance of Process Optimization

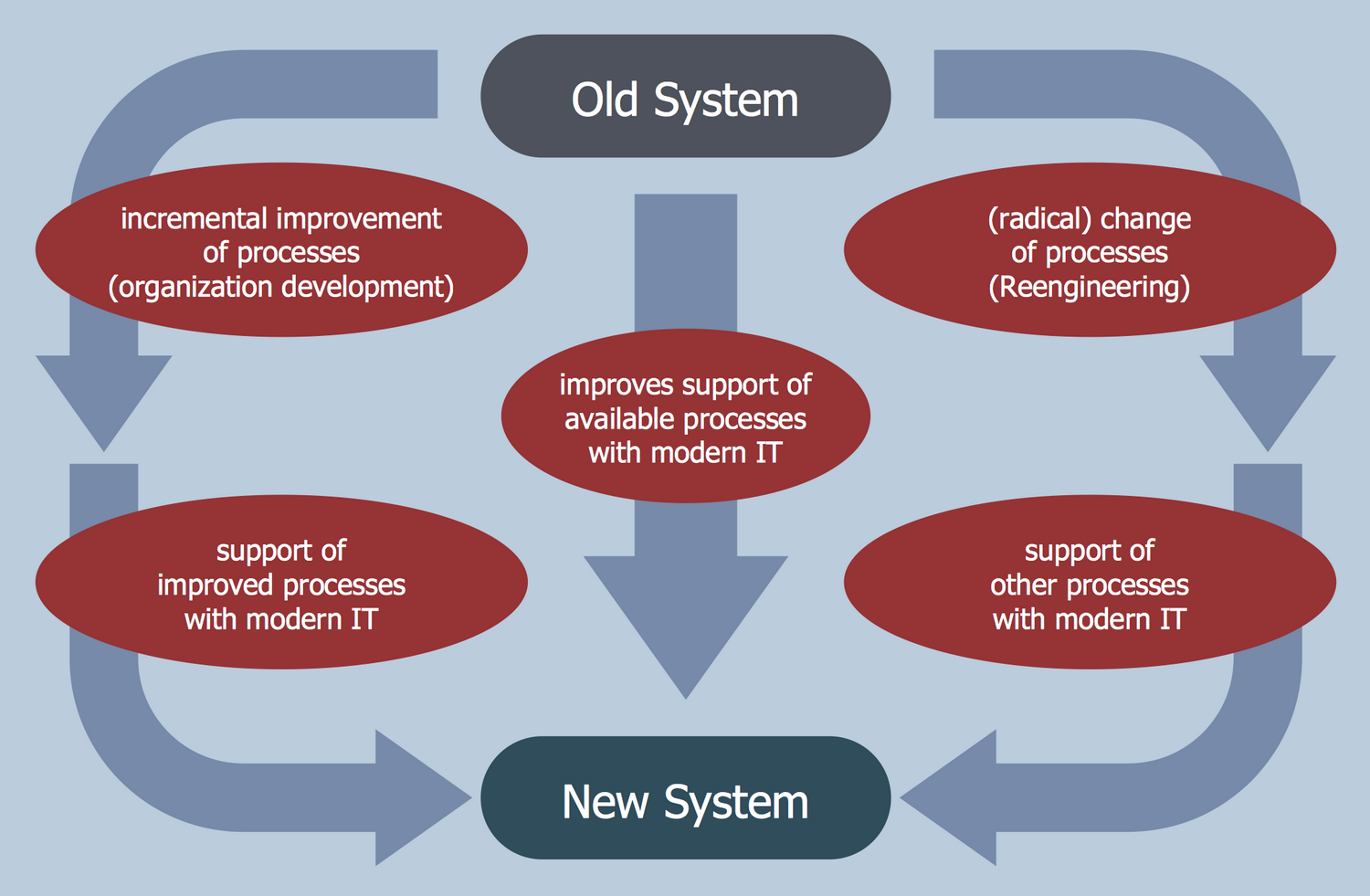

The traditional approach to business often involves a ‘one-size-fits-all’ mentality, where processes are implemented without considering their individual needs or potential for improvement. This can lead to bottlenecks, wasted time, and frustrated employees. Business process optimization strategies recognize that each business operates differently and requires tailored solutions. Ignoring these differences can result in significant inefficiencies and lost opportunities. Investing in process improvement isn’t just about making things faster; it’s about creating a more agile, responsive, and ultimately, more successful organization. The benefits extend beyond simple cost savings; they encompass improved customer satisfaction, increased employee morale, and a stronger competitive advantage. Consider the ripple effect of streamlined processes – reduced errors, faster turnaround times, and a more consistent customer experience.

Identifying Bottlenecks and Inefficiencies

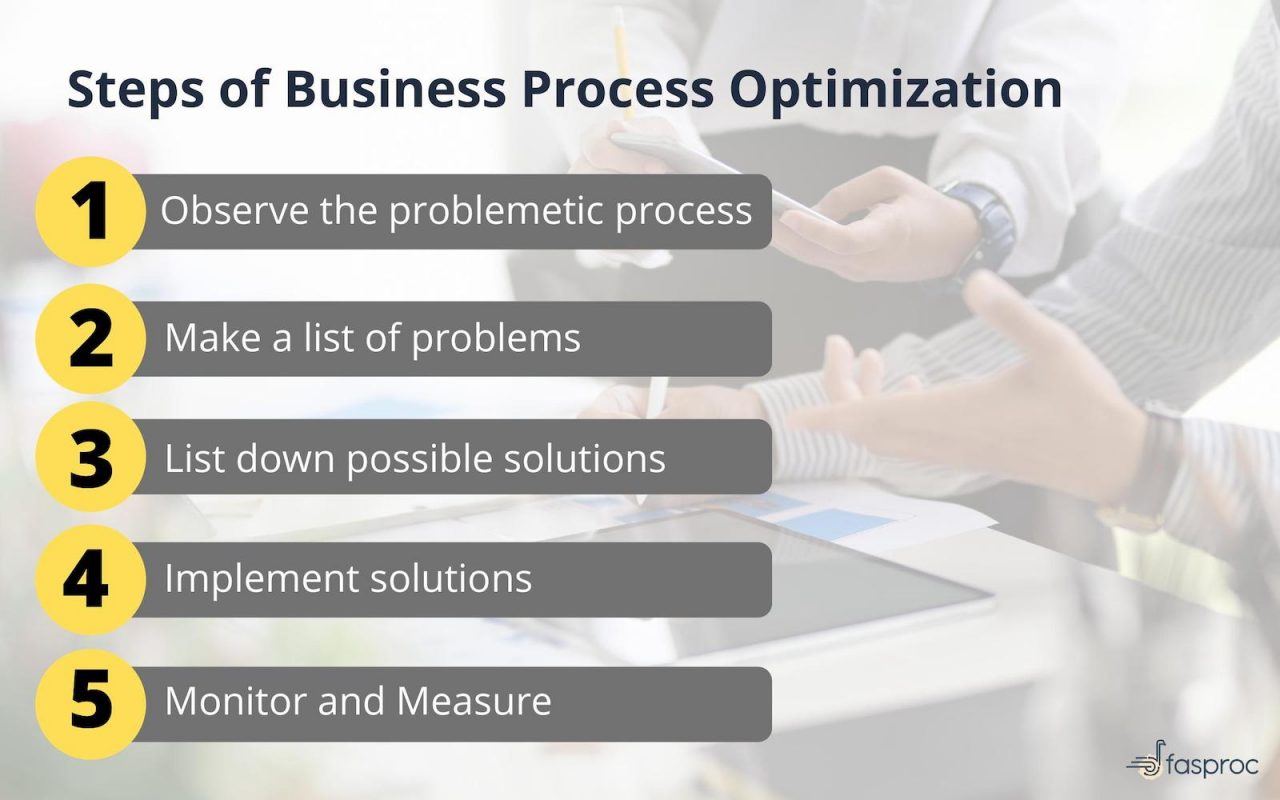

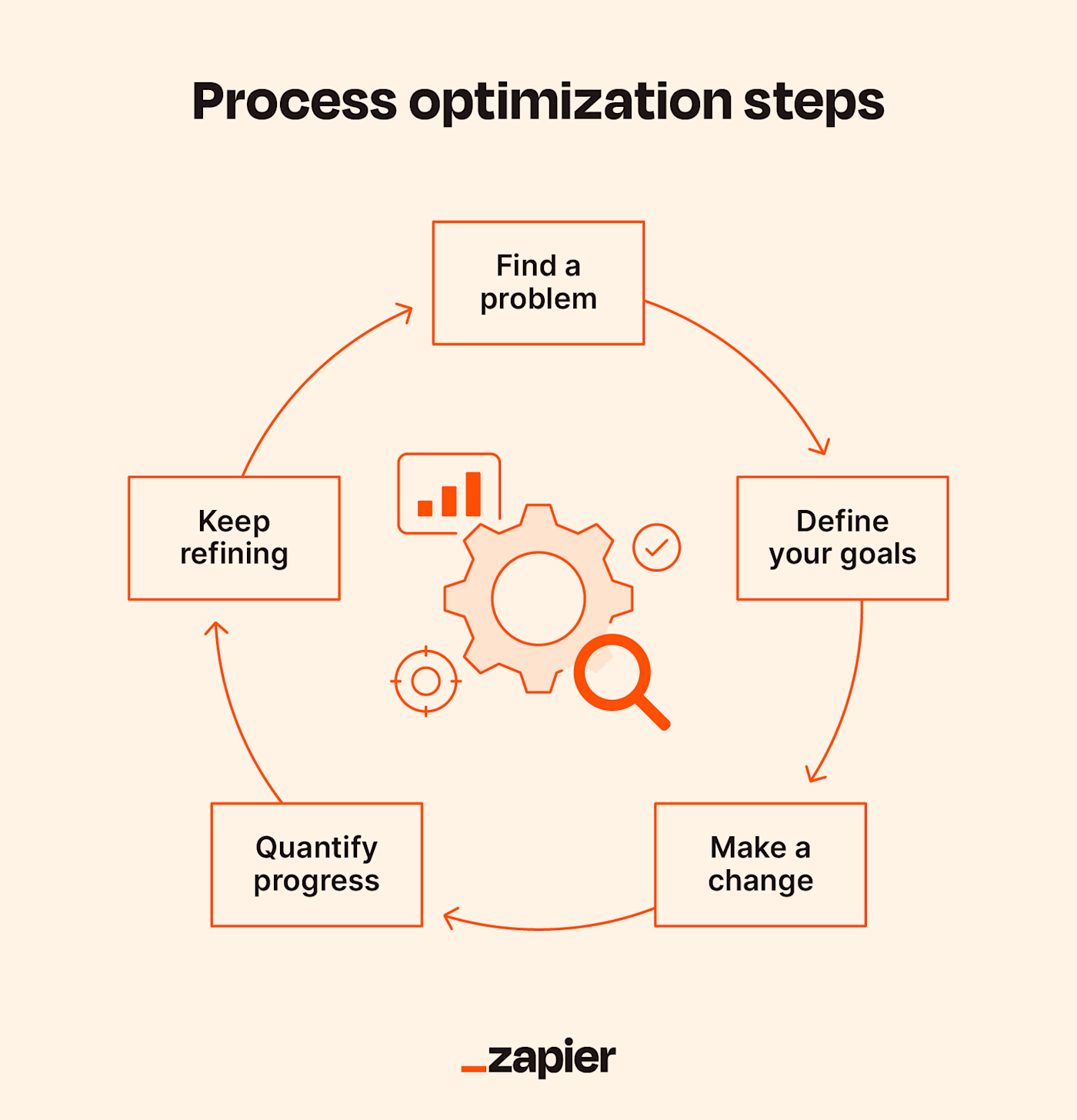

The first step towards effective process optimization is identifying where things are failing. This often involves a thorough assessment of your existing workflows. Don’t just assume you know where things go wrong; actively seek out pain points. Several methods can be employed to pinpoint bottlenecks:

- Process Mapping: Create visual representations of your key processes – flowcharts are excellent for this. This helps to understand the steps involved, identify redundancies, and pinpoint areas where delays or errors occur.

- Value Stream Mapping: This technique focuses on the entire flow of materials and information, from the initial request to the final delivery. It highlights waste and inefficiencies across the entire process.

- Employee Interviews & Surveys: Talk to your employees who are directly involved in the processes. They often have invaluable insights into what’s working well and what’s not. Anonymous surveys can also provide a broader perspective.

- Data Analysis: Leverage your existing data – sales data, customer service logs, inventory reports – to identify trends and patterns that indicate inefficiencies. Look for recurring errors, long processing times, and high error rates.

Common Bottlenecks to Watch Out For

Several common bottlenecks frequently plague businesses:

- Lack of Standardization: Varying processes across different departments or teams leads to inconsistencies and errors.

- Manual Data Entry: Reliance on manual data entry is time-consuming, prone to errors, and limits scalability.

- Excessive Redundancy: Multiple steps in a process that don’t add value.

- Poor Communication: Lack of clear communication between departments or teams can lead to misunderstandings and delays.

- Lack of Automation: Processes that are not automated are often inefficient and costly.

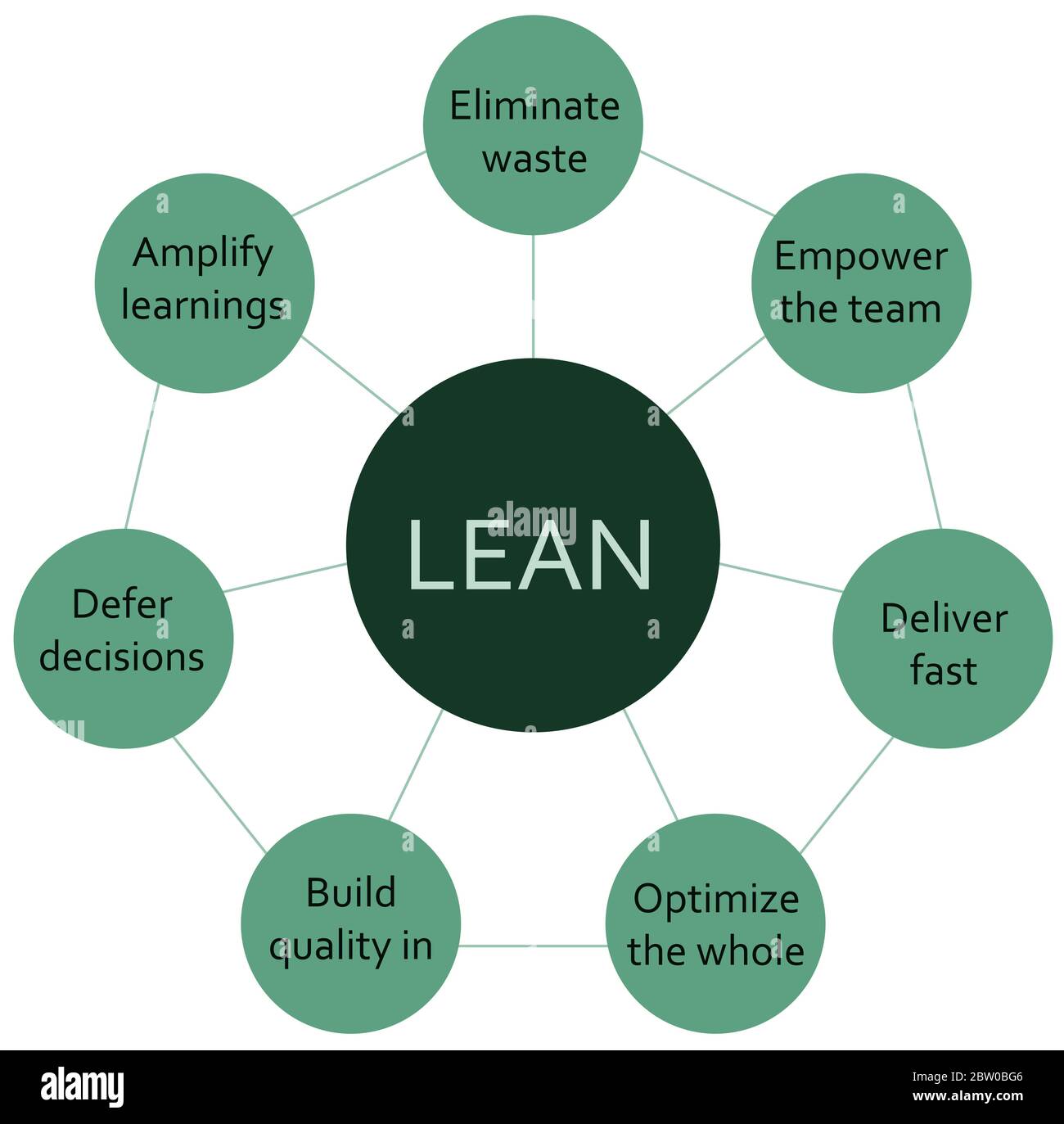

Implementing Lean Principles for Process Improvement

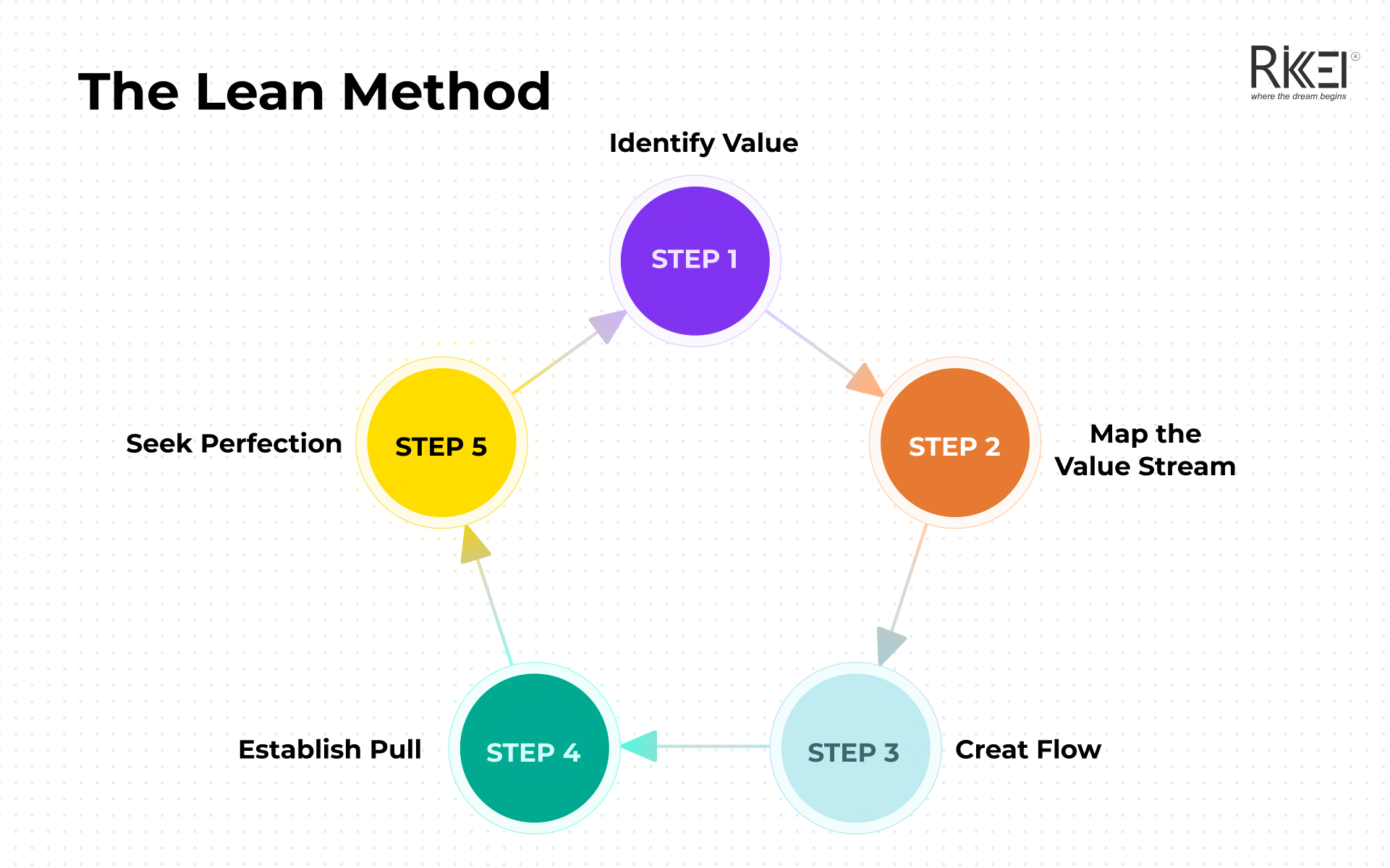

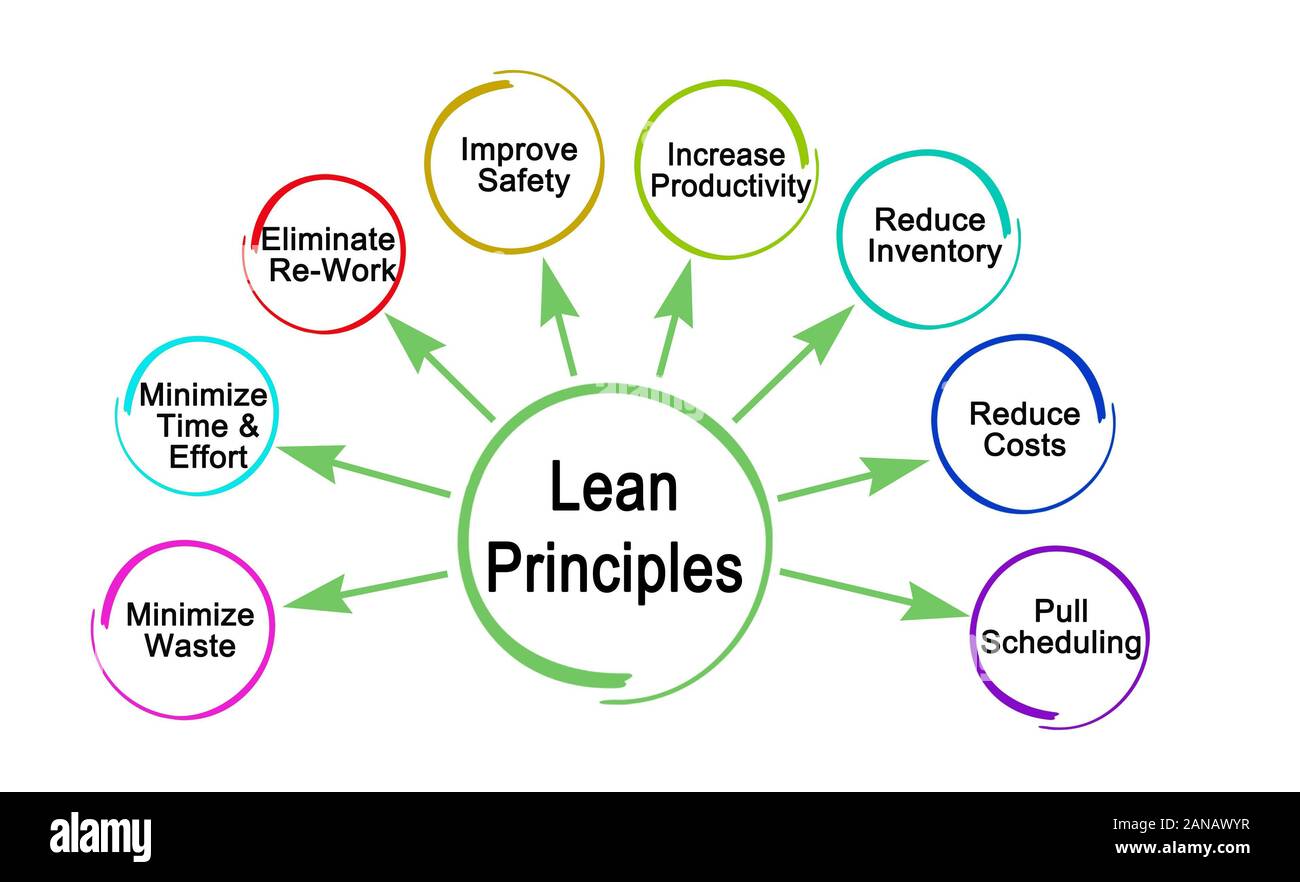

Lean principles offer a powerful framework for driving process optimization. Lean focuses on eliminating waste – anything that doesn’t add value to the customer. Key Lean concepts include:

- Value Stream Mapping: As mentioned earlier, this is fundamental to identifying and eliminating waste.

- 5S Methodology: A system for organizing and maintaining a clean, efficient, and safe workplace.

- Kaizen: Continuous improvement – a philosophy of small, incremental changes that lead to significant results.

- Just-in-Time (JIT) Inventory: Minimizing inventory levels to reduce storage costs and waste.

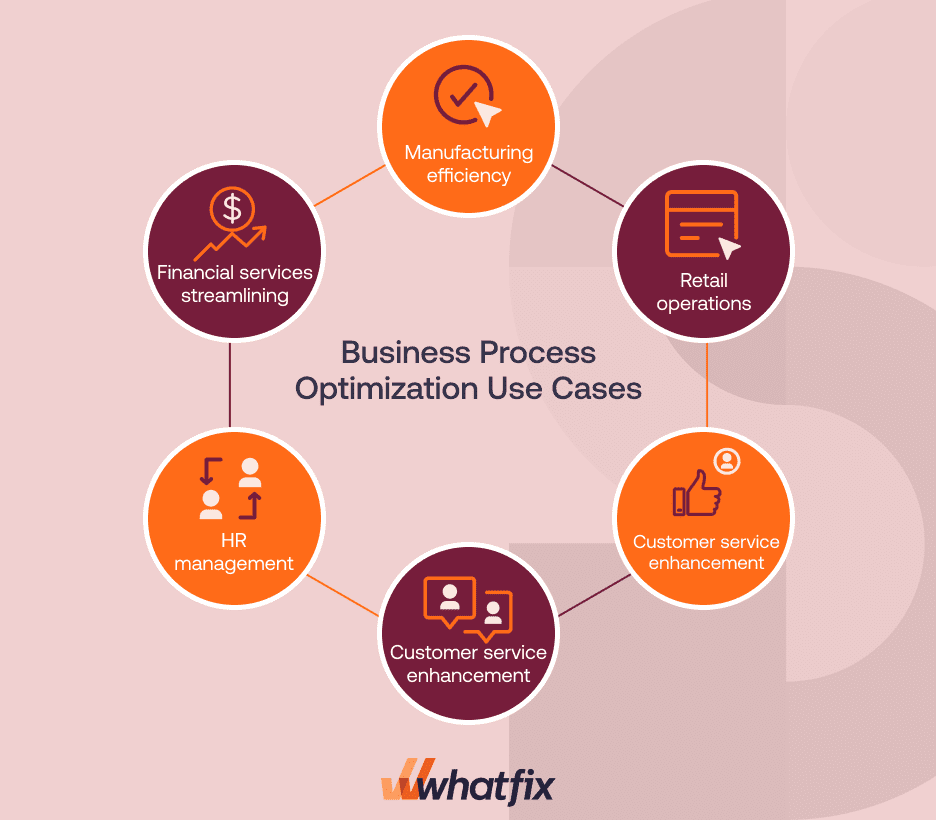

Specific Optimization Strategies for Different Types of Processes

The best approach to process optimization depends heavily on the specific type of process you’re looking to improve. Here are some examples:

Streamlining Order Fulfillment

Order fulfillment is often a complex and time-consuming process. Optimization strategies include:

- Automating Order Processing: Implement software to automate order entry, inventory management, and shipping.

- Implementing a Warehouse Management System (WMS): A WMS can improve inventory accuracy, reduce picking errors, and optimize warehouse layout.

- Optimizing Shipping Routes: Use route optimization software to minimize shipping costs and delivery times.

- Clear Order Tracking: Provide customers with real-time order tracking information.

Improving Customer Service

Customer service is a critical area for optimization. Strategies include:

- Implementing a CRM (Customer Relationship Management) System: A CRM helps to manage customer interactions and provide personalized service.

- Developing Standardized Responses: Create templates for common customer inquiries to ensure consistent and accurate responses.

- Empowering Customer Service Representatives: Give them the authority to resolve customer issues quickly and efficiently.

- Proactive Customer Service: Anticipate customer needs and address potential issues before they arise.

Enhancing Internal Communication

Poor internal communication can significantly hinder process efficiency. Consider:

- Implementing a Collaborative Communication Platform: Tools like Slack, Microsoft Teams, or Google Workspace can facilitate real-time communication and information sharing.

- Regular Team Meetings: Schedule regular meetings to discuss progress, address challenges, and share best practices.

- Clear Documentation: Ensure all processes and procedures are clearly documented and easily accessible to all employees.

Measuring the Success of Process Optimization

It’s crucial to measure the impact of your optimization efforts. Don’t just implement changes and hope for the best. Track key metrics to assess whether your efforts are delivering the desired results. Some common metrics include:

- Cycle Time: The time it takes to complete a process.

- Error Rate: The number of errors or mistakes made during a process.

- Cost Savings: The amount of money saved through process optimization.

- Customer Satisfaction: Measured through surveys and feedback.

- Employee Productivity: Increased output per employee.

Conclusion

Business process optimization strategies are not a one-time project; they are an ongoing journey of continuous improvement. By systematically identifying bottlenecks, implementing lean principles, and tracking key metrics, businesses can unlock significant gains in efficiency, productivity, and profitability. The key is to adopt a data-driven approach, focusing on the areas that will have the greatest impact on your organization’s bottom line. Remember that business process optimization strategies are a fundamental investment in the future success of your business. Don’t underestimate the power of streamlining your operations – it’s a powerful tool for achieving sustainable growth and competitive advantage. Investing in these strategies will undoubtedly yield significant returns.