Equipment failure is a costly and disruptive event for any business. It can lead to production downtime, revenue loss, and potential safety hazards. Proactive and diligent equipment maintenance is not just about preventing breakdowns; it’s about maximizing equipment lifespan, improving operational efficiency, and ultimately, reducing overall costs. This article will delve into the essential best practices for maintaining your equipment, ensuring smooth operations and minimizing costly repairs. Equipment maintenance is a critical investment, and understanding the principles behind it is paramount. It’s about understanding why things break and then implementing strategies to prevent those failures. Ignoring preventative measures can quickly escalate into significant problems. Let’s explore how to build a robust maintenance program.

Understanding the Importance of Equipment Maintenance

The benefits of consistent equipment maintenance extend far beyond simple repairs. A well-maintained equipment fleet contributes significantly to a company’s bottom line. Firstly, it directly impacts productivity. When equipment operates reliably, production lines remain efficient, leading to higher output and increased revenue. Secondly, preventative maintenance reduces unexpected downtime. Scheduled inspections and timely repairs minimize the risk of breakdowns, ensuring that operations don’t be thrown into chaos. Thirdly, adherence to maintenance schedules can significantly lower repair costs. Addressing small issues before they escalate into major problems is far more economical than dealing with extensive and expensive repairs. Finally, maintaining equipment compliance with safety regulations is a crucial aspect of responsible operation. Proper maintenance ensures equipment operates within acceptable limits, minimizing the risk of accidents and injuries. Equipment maintenance is therefore a fundamental pillar of operational excellence.

Core Maintenance Tasks: A Detailed Breakdown

A comprehensive equipment maintenance program typically involves a multi-faceted approach. Here’s a breakdown of key tasks and best practices:

Lubrication – The Foundation of Smooth Operation

Lubrication is arguably the most fundamental aspect of equipment maintenance. Proper lubrication reduces friction, minimizes wear, and extends the lifespan of moving parts. Lubrication schedules should be based on operating conditions, temperature, and the specific equipment. Regularly checking and replenishing lubricants is crucial. Consider using high-quality lubricants specifically designed for the equipment being maintained. Don’t just rely on generic oils; understanding the properties of the lubricant is key. Different metals require different lubricants – for example, stainless steel often benefits from a specialized lubricant to prevent corrosion. Furthermore, consider using lubricant additives that can enhance performance and extend the lifespan of the equipment. Proper training for maintenance personnel on lubricant selection and application is essential.

Inspection – Spotting Potential Problems Early

Regular inspections are the cornerstone of proactive maintenance. Visual inspections, combined with more detailed testing, can reveal potential problems before they lead to catastrophic failures. This includes checking for wear and tear on belts, hoses, seals, and bearings. Inspection checklists should be developed and followed consistently. Don’t just look at the obvious; pay attention to subtle signs of wear, such as discoloration, cracking, or looseness. Using non-destructive testing methods, like infrared thermography, can provide valuable insights into hidden damage. Document all inspections and findings, creating a record for future reference. Consider using automated inspection systems for repetitive tasks, improving accuracy and efficiency.

Cleaning – Removing Contaminants and Maintaining Performance

Dirt, debris, and corrosive substances can significantly degrade equipment performance. Regular cleaning is essential for maintaining optimal functionality. This includes cleaning filters, screens, and other components that can trap contaminants. Cleaning procedures should be tailored to the specific equipment and the type of contaminants present. Using appropriate cleaning agents and techniques is vital to avoid damaging the equipment. Consider using automated cleaning systems for large-scale cleaning operations. Properly disposing of cleaning waste is also a critical aspect of environmental responsibility.

Component Replacement – Addressing Wear and Tear

Over time, components will inevitably wear out, requiring replacement. Component replacement should be planned and executed strategically, considering the equipment’s age, operating conditions, and the cost of replacement versus the cost of repair. A parts inventory should be maintained to ensure timely replacement of critical components. Consider using predictive maintenance techniques, which analyze equipment data to anticipate component failures and schedule replacements proactively. Proper documentation of all component replacements is crucial for traceability and warranty claims.

Belt and Hose Inspection and Replacement

Belts and hoses are frequently overlooked but are critical for smooth operation. They can stretch, fray, or crack, leading to vibration, misalignment, and potential failure. Regularly inspect belts for wear and tear, and replace them when necessary. Hoses should be checked for leaks, cracks, and swelling. Using appropriate replacement materials is essential to ensure durability and performance. Consider using vibration monitoring systems to detect early signs of belt or hose problems.

Fluid Analysis – Monitoring System Health

Many equipment systems rely on fluids (oil, coolant, hydraulic fluid, etc.) to lubricate and cool components. Regular fluid analysis is crucial for monitoring system health and identifying potential problems. Analyzing fluid composition can reveal contaminants, wear particles, and other indicators of degradation. This information can be used to optimize fluid changes and prevent costly repairs. Consider using laboratory testing to accurately determine fluid properties.

The Importance of a Preventative Maintenance Program

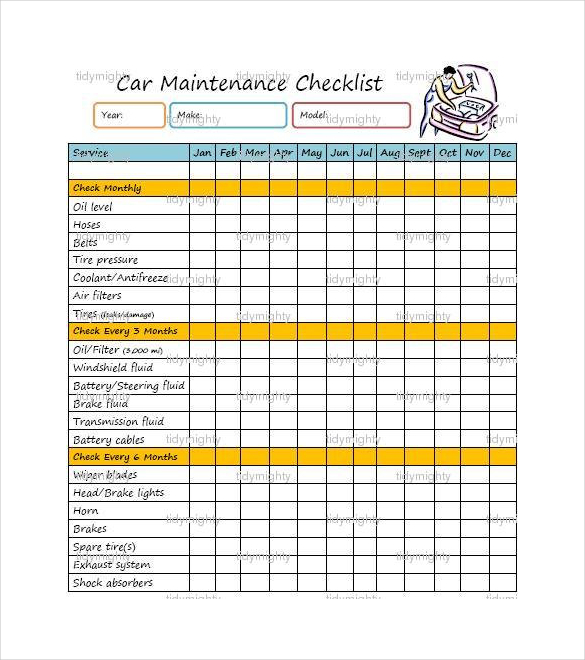

A well-defined preventative maintenance program is far more effective than reactive repairs. It’s a proactive approach that minimizes downtime, extends equipment lifespan, and reduces overall maintenance costs. A typical preventative maintenance program might include:

- Daily Checks: Visual inspections for leaks, loose connections, and unusual noises.

- Weekly Checks: Lubrication, filter changes, and component inspections.

- Monthly Checks: More detailed inspections, including temperature monitoring and vibration analysis.

- Annual Inspections: Comprehensive assessments of all equipment systems.

Implementing a robust preventative maintenance program requires careful planning, scheduling, and training. It’s not just about following a checklist; it’s about understanding why things break and implementing strategies to prevent those failures. Investing in the right tools and technologies, such as data logging systems and predictive analytics, can significantly enhance the effectiveness of the program.

Conclusion

Equipment maintenance is a continuous process, not a one-time event. By implementing a comprehensive maintenance program, businesses can ensure the reliable operation of their equipment, minimize downtime, and maximize productivity. Equipment maintenance is an investment, not an expense. It’s a strategic decision that pays dividends in the long run. Prioritizing preventative measures, understanding the root causes of equipment failures, and investing in the right tools and expertise are key to achieving optimal operational performance. Ultimately, equipment maintenance is about safeguarding assets, protecting people, and ensuring business continuity. Don’t underestimate the value of a proactive approach – it’s the difference between a smooth operation and a costly breakdown. Continuous improvement in maintenance practices is always beneficial.