Manufacturing processes are the backbone of modern economies, transforming raw materials into finished goods that meet consumer demands. They’re far more than just assembly lines; they’re a complex, multi-stage system involving numerous interconnected activities, technologies, and skilled personnel. Understanding these processes is crucial for businesses of all sizes, from small startups to multinational corporations. This article will delve into the core elements of manufacturing, exploring different types, key challenges, and emerging trends shaping the industry. The central focus will be on the intricate dance of operations that drive the creation of products we use every day. Manufacturing processes are constantly evolving, driven by technological advancements, increasing global competition, and a growing emphasis on sustainability. Let’s begin our exploration of this vital sector.

The Stages of Manufacturing

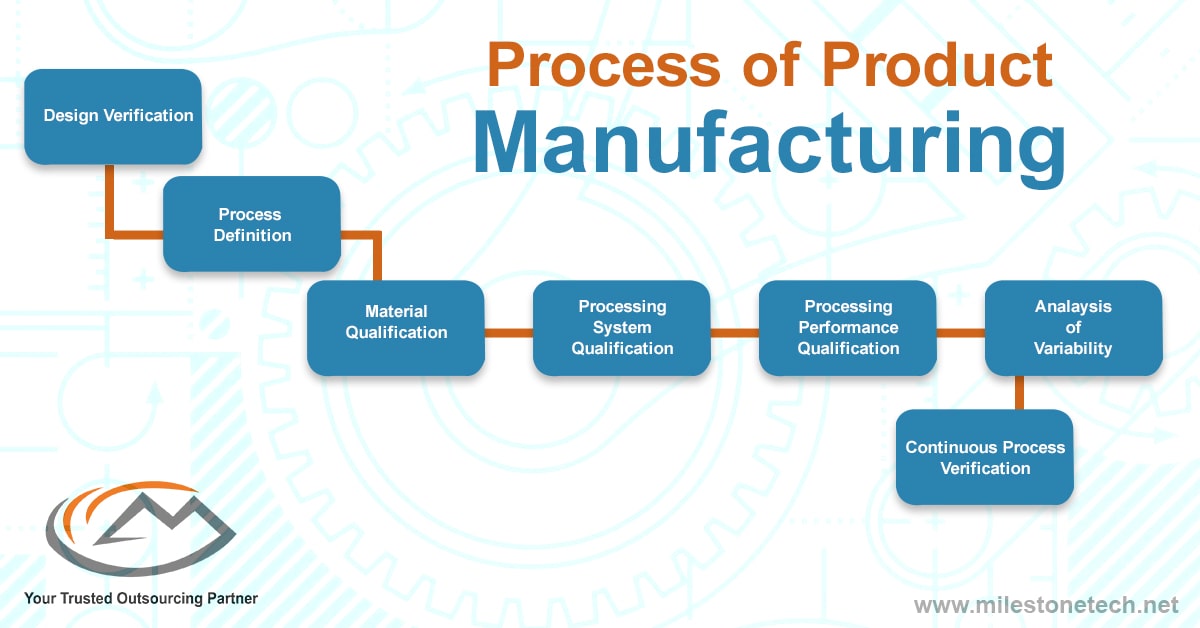

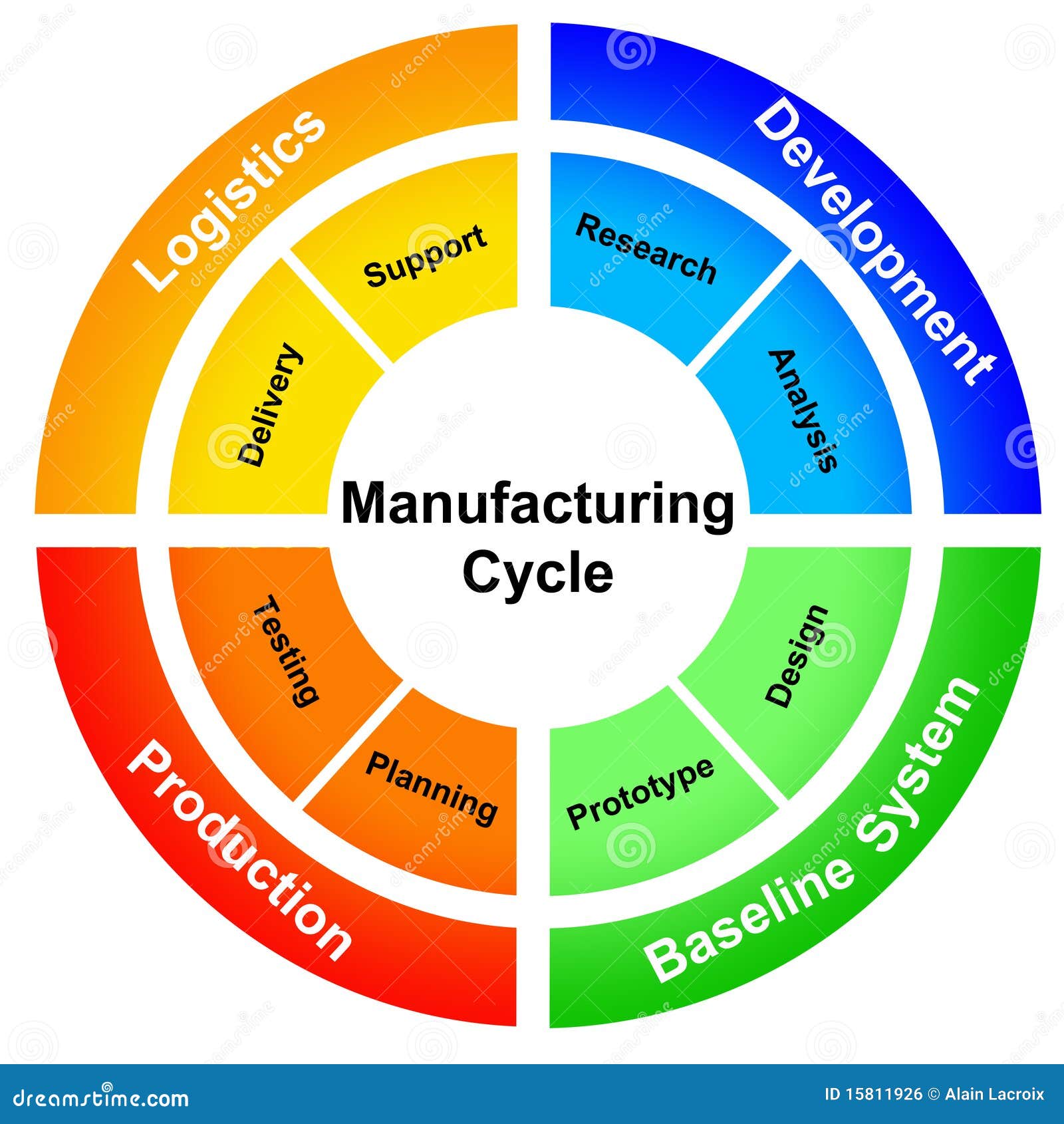

The journey of a product from raw materials to the consumer is rarely a linear one. It typically involves several distinct stages, each requiring careful planning and execution. These stages often overlap and are interconnected, creating a dynamic and responsive system. A simplified overview includes:

- Design & Engineering: This initial phase involves conceptualizing the product, creating detailed blueprints, and selecting appropriate materials and technologies. It’s heavily reliant on research and development (R&D) to ensure the product meets market needs and specifications. Sophisticated CAD/CAM software is increasingly used to streamline this process.

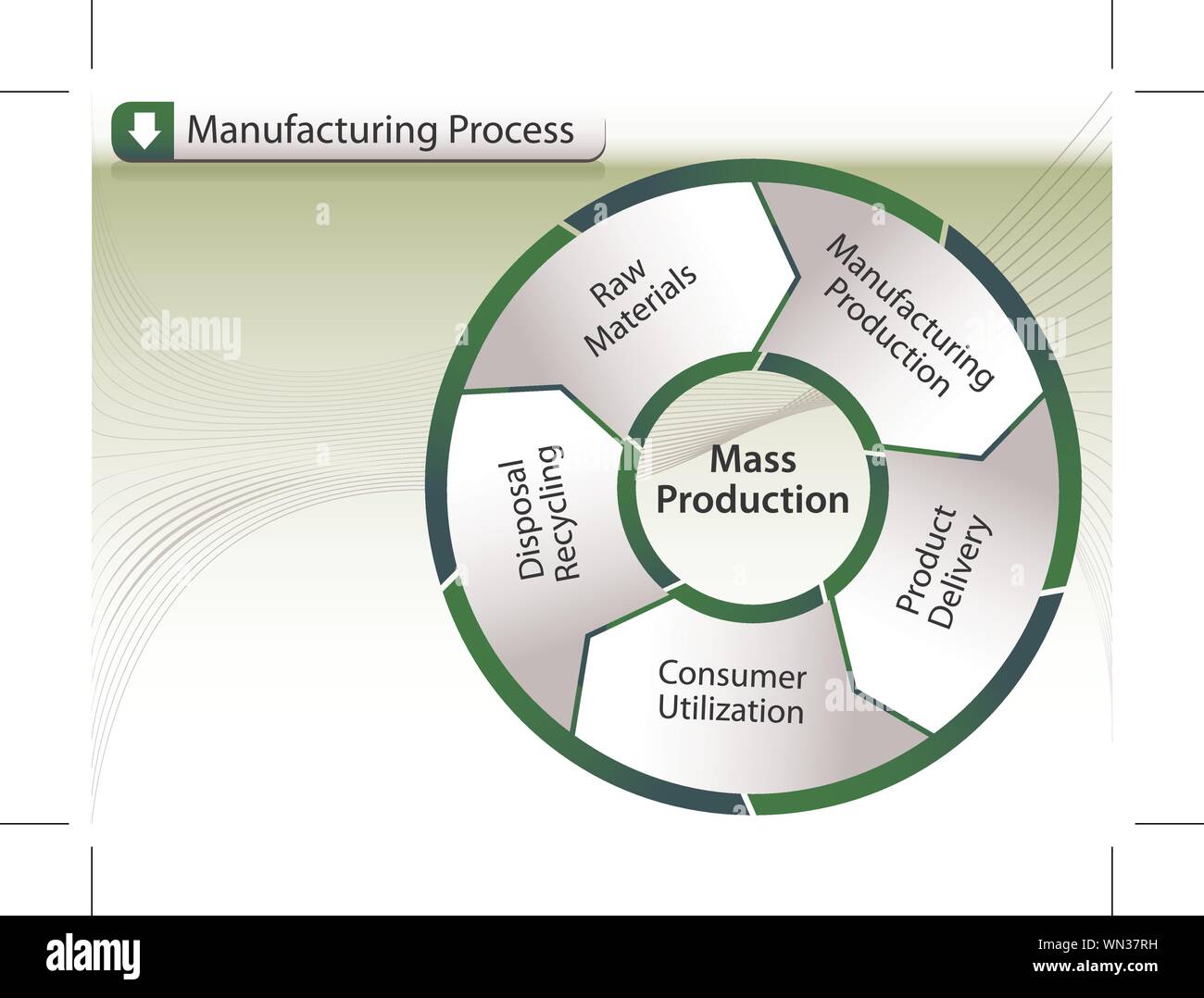

- Procurement: This stage focuses on sourcing the necessary raw materials, components, and equipment. Effective procurement strategies are vital for controlling costs and ensuring timely delivery. Supply chain management plays a critical role here, involving logistics, supplier relationships, and inventory control.

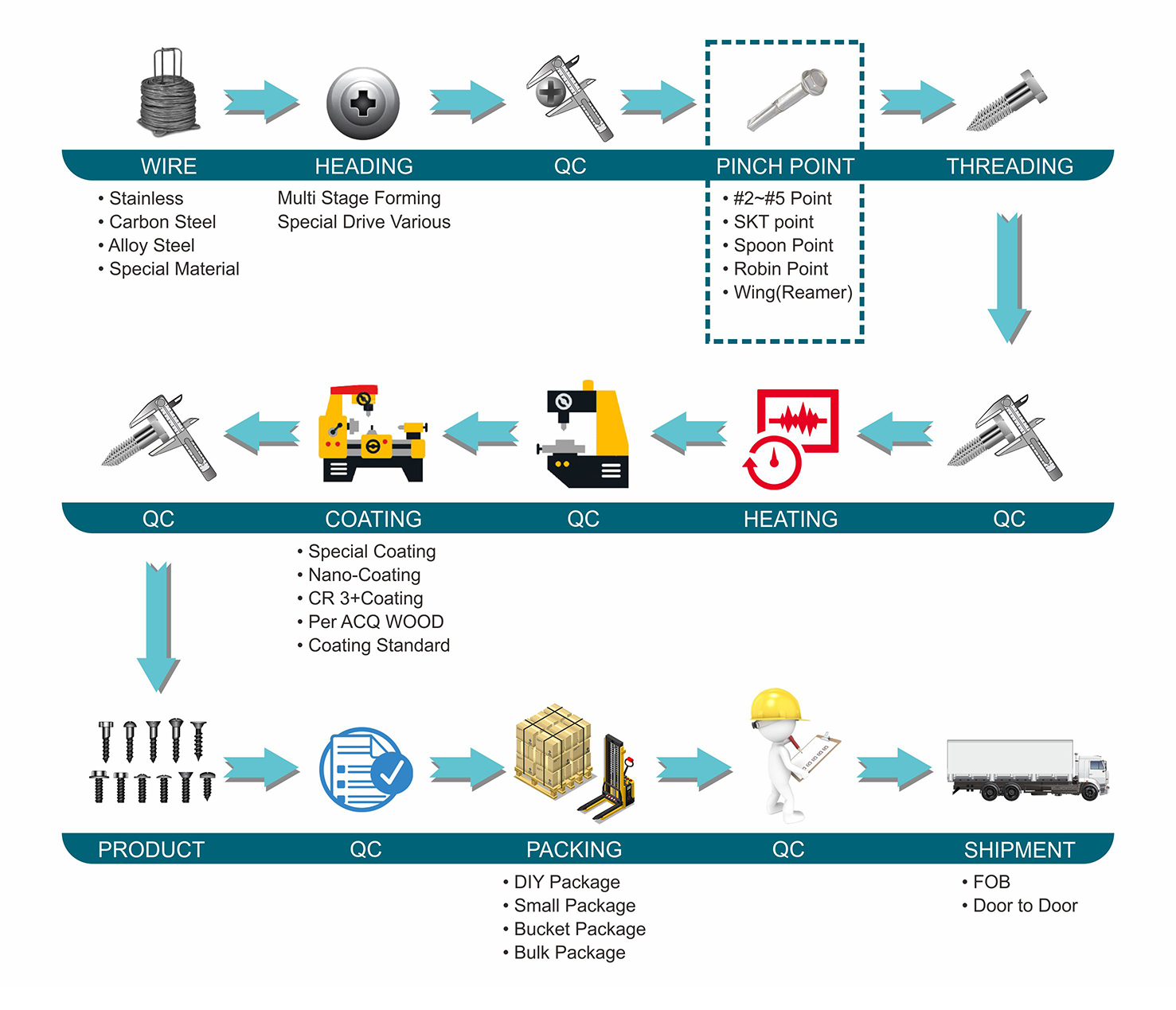

- Production: This is where the actual manufacturing takes place. Different methods of production exist, each suited to specific products and scale. These can range from mass production using automated machinery to bespoke, handcrafted techniques. Quality control measures are implemented at every stage to ensure consistent product quality.

- Assembly & Testing: Once the product is manufactured, it undergoes assembly and rigorous testing to verify its functionality and meet performance standards. This often involves specialized equipment and trained technicians. Testing includes functional testing, durability testing, and environmental testing.

- Packaging & Distribution: The final stage involves packaging the product to protect it during shipping and handling, and then distributing it to retailers or directly to consumers. Efficient logistics and distribution networks are essential for reaching the target market.

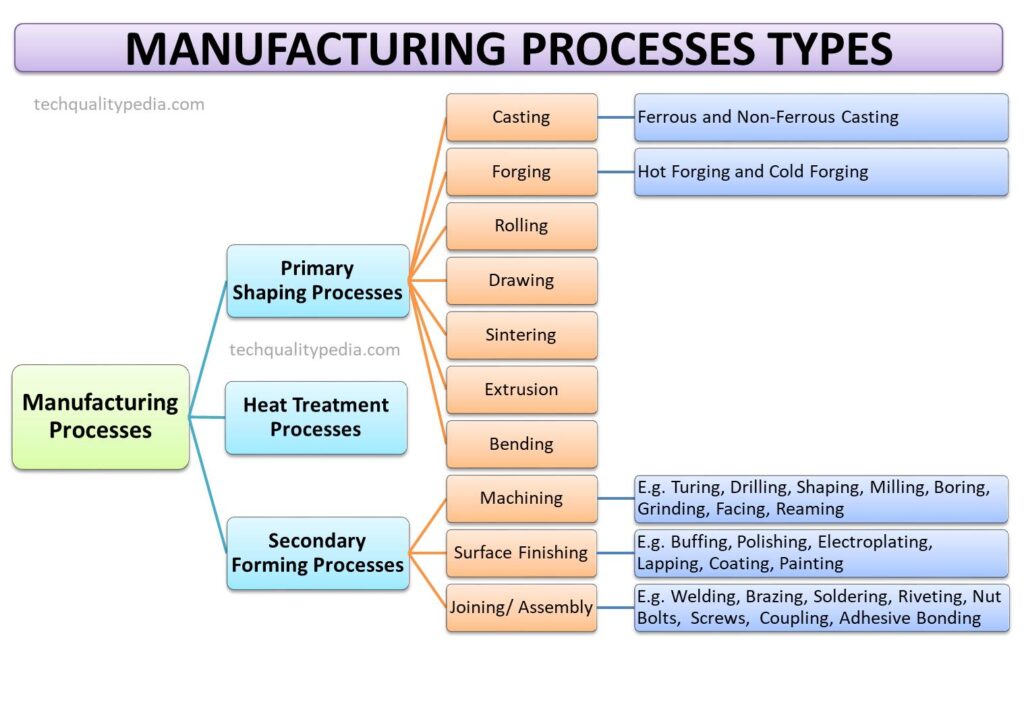

Different Types of Manufacturing Processes

The specific methods employed within each stage vary significantly depending on the product, industry, and scale of operation. Here are a few examples:

- Additive Manufacturing (3D Printing): This technology allows for the creation of complex geometries by layering materials, rather than simply joining them. It’s revolutionizing industries like aerospace, automotive, and medical device manufacturing. The ability to prototype and produce customized parts quickly is a major advantage.

- Robotic Manufacturing: Robots are increasingly being used to automate repetitive tasks, improving efficiency and reducing labor costs. They are particularly effective in high-volume production environments. Collaborative robots (cobots) work alongside human workers, enhancing safety and productivity.

- Lean Manufacturing: This methodology focuses on eliminating waste and optimizing processes to improve efficiency and reduce costs. It emphasizes continuous improvement and employee involvement.

- CNC Machining: Computer Numerical Control (CNC) machines precisely cut, shape, and form materials using computer-generated instructions. This is widely used for producing intricate parts and components.

- Cast Manufacturing: This process involves pouring molten material into a mold to create a three-dimensional shape. It’s commonly used for producing metal parts.

Key Challenges in Manufacturing Processes

Despite advancements in technology, manufacturing processes still face numerous challenges. Addressing these challenges is critical for maintaining competitiveness and achieving sustainable growth.

- Supply Chain Disruptions: Global events, geopolitical instability, and natural disasters can significantly disrupt supply chains, leading to delays and increased costs. Diversifying suppliers and building resilient supply networks are crucial mitigation strategies.

- Labor Shortages: Many countries are experiencing labor shortages in skilled trades, impacting production capacity. Investing in training and education programs is essential to address this issue.

- Rising Material Costs: Fluctuations in raw material prices can significantly impact manufacturing costs. Implementing strategies like strategic sourcing and long-term contracts can help mitigate this risk.

- Sustainability Concerns: Manufacturers are facing increasing pressure to reduce their environmental footprint. This includes minimizing waste, conserving energy, and using sustainable materials. Circular economy principles are gaining traction.

- Cybersecurity Threats: Connected manufacturing systems are vulnerable to cyberattacks, which can disrupt operations and compromise sensitive data. Robust cybersecurity measures are essential.

The Role of Technology in Manufacturing

Technology is fundamentally transforming the manufacturing landscape. Automation, artificial intelligence (AI), the Internet of Things (IoT), and cloud computing are all playing increasingly important roles.

- Artificial Intelligence (AI): AI is being used to optimize production processes, predict equipment failures, and improve quality control. Machine learning algorithms analyze vast amounts of data to identify patterns and trends.

- Internet of Things (IoT): IoT devices, such as sensors and actuators, collect real-time data about equipment performance and production processes. This data can be used to monitor, diagnose, and optimize operations.

- Cloud Computing: Cloud-based platforms provide manufacturers with access to scalable computing resources, data storage, and collaboration tools.

- Robotics and Automation: Robots are increasingly being used to automate tasks, improve efficiency, and reduce labor costs.

Future Trends in Manufacturing

Looking ahead, several key trends are expected to shape the future of manufacturing.

- Industry 4.0: This concept encompasses the integration of digital technologies into all aspects of manufacturing, creating a truly connected and intelligent production system.

- Additive Manufacturing (3D Printing) Expansion: 3D printing will continue to expand its applications, enabling the creation of customized products and complex geometries.

- Digital Twins: Digital twins – virtual representations of physical assets – are becoming increasingly popular, allowing manufacturers to simulate and optimize operations.

- Sustainable Manufacturing: Manufacturers will increasingly focus on reducing their environmental footprint through circular economy principles, waste reduction, and the use of sustainable materials.

- Human-Machine Collaboration: The future of manufacturing will involve a greater emphasis on human-machine collaboration, leveraging the strengths of both humans and machines.

Conclusion

Manufacturing processes are a complex and dynamic system that underpins the global economy. Understanding the various stages, types, and challenges involved is crucial for businesses seeking to thrive in today’s competitive environment. The ongoing integration of technology, particularly automation and AI, is driving significant changes across the industry. Addressing supply chain vulnerabilities, promoting workforce development, and prioritizing sustainability are key priorities for manufacturers. As we move forward, the focus will increasingly be on creating flexible, responsive, and intelligent manufacturing systems that can adapt to the ever-changing demands of the market. Manufacturing processes are not simply about producing goods; they are about innovation, efficiency, and creating value. By embracing these advancements and adapting to the evolving landscape, manufacturers can secure their future success.